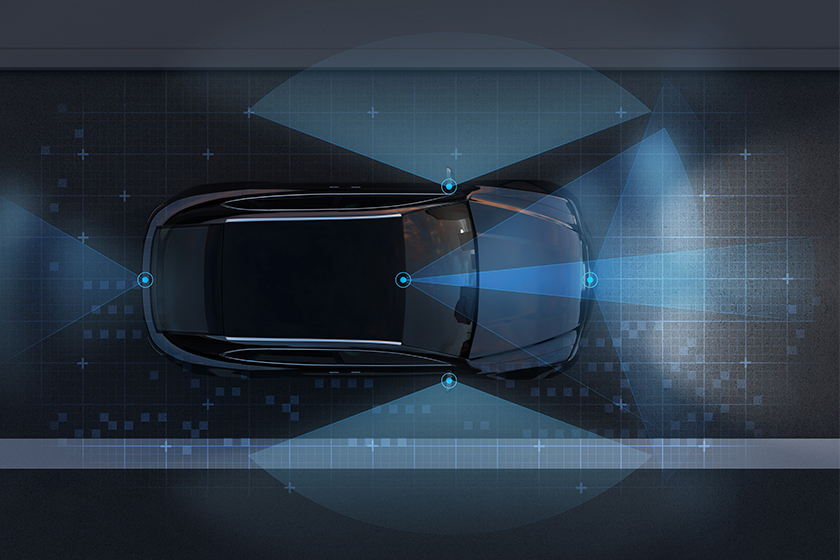

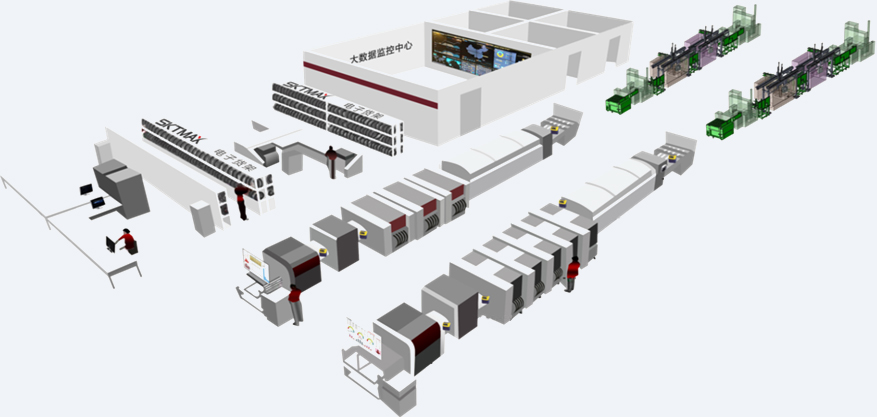

Intelligent management system

Intelligent management system

The company has SAP, data center, OA, PLM, SRM, CRM, MES, WMS, AIM, Zen, order review

E-HR and other information management systems can record and manage every production action, and track every step of the product process at any time.